Areas of application for cleaning systems

Our applications in the field of cleaning and degreasing

Applications

We offer cleaning systems for a wide range of industries.

The design of an EVT cleaning system always starts with the consideration of the parts to be cleaned, their geometry, dimensions and characteristics.

The machining processes before and after the degreasing process and the desired degree of cleaning of the parts, justify the choice of the appropriate cleaning medium.

We look forward to an individual consultation!

Turning and milling technology

Degreasing systems for turned and milled parts

The plants can be loaded and unloaded manually or equipped with fully automatic feeding devices which allow unmanned operation for up to several hours.

Optics

Cleaning optical components

Many tasks in the optical industry have already been realized by us with different cleaning media. EVT systems of several series are used by well-known companies in this industry.

We would like to invite you to visit our factory in Sternenfels. Here we can explain details in practice, discuss initial approaches to realization and carry out cleaning tests in our technical center.

Airplane, Helicopter and Propulsion systems

Degreasing for engine parts

The degreasing of engine parts, honeycombs for stabilizing wings, rotor blades, landing gear parts, etc. requires very special options above and beyond the standards of a mature process technology in order to perfectly treat even critical and difficult-to-clean zones of the parts. Safety and quality are always our top priorities.

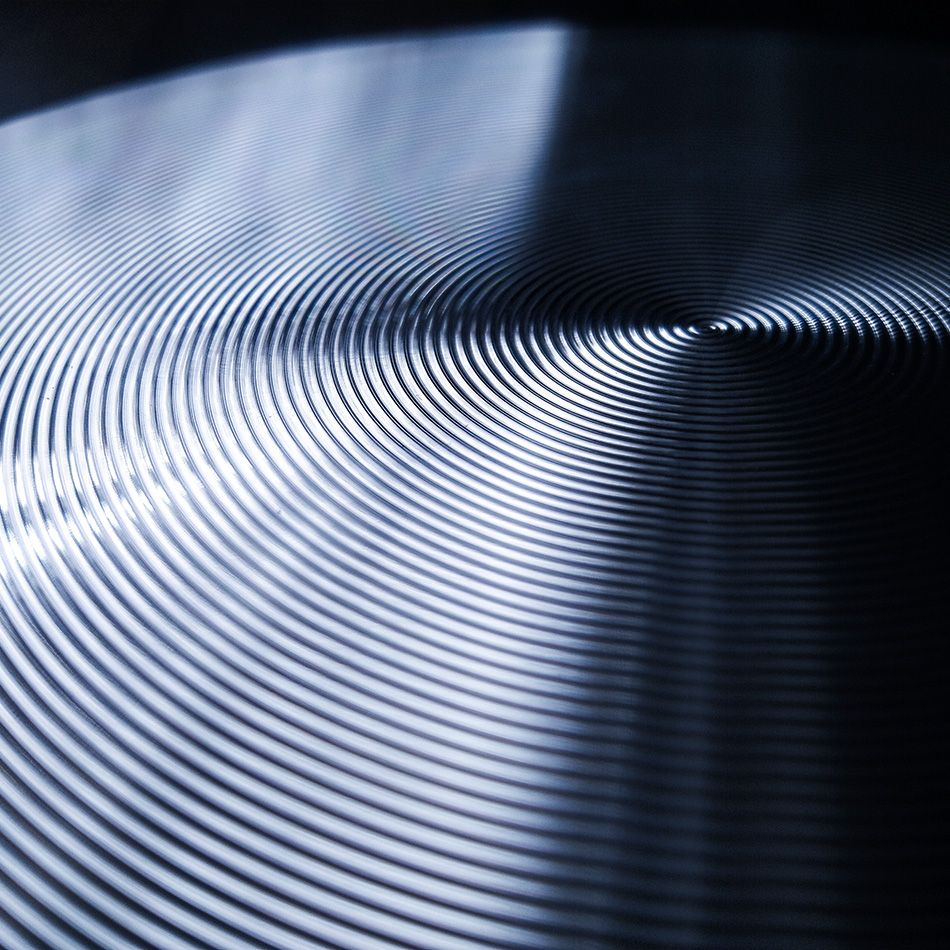

Pipes and Coils

Interior degreasing for pipes

Another innovation is our solution for the degreasing of tube coils.

For the cleaning of tube coils, there are different possibilities of connections, so that different inner diameters can be processed in one system. Also the outside cleaning of the tubes can be combined with the inside cleaning within one plant. We have experience for lengths up to 3 km.

Die cutting and forming

Special cleaning technology for stamped parts

Our sophisticated process technology guarantees that even complicated parts with unusual geometry and undercuts are perfectly cleaned. After degreasing, our drying processes ensure rapid drying of the parts and speedy decontamination of the working chamber to enable the fastest possible batch times.

Contract degreasing

Tailored to your requirements

Here, systems with large working chambers that can withstand plenty of weight and have numerous cleaning options are in demand. Flooding, spraying, turning, vacuum distillation, chip filters, etc. are standard in these applications.

Our many years of experience as a reliable partner to contract manufacturers, makes our plant technology highly suitable for your requirements.

Heat Treatment

Degreasing for ideal heat treatment

Similarly, the glowing steel or cast iron parts are quenched in an oil bath. Following this procedure, the removal of the oil from the part is required in any case. The EVT-GIGANT machines are partly especially designed for this process step before and/or after hardening. Batch weights of up to 14 tons have already been realized here.

The advantage of non-flammable solvents, such as CHCs (chlorinated hydrocarbons), is that the curing oven and cleaning system can be located in the immediate vicinity of each other. In this way, the available space in the production hall can be optimally utilized. EVT plants can be loaded in different ways: Rail car, robot, manually, automatically or with an ant.

Plastics and Adhesives

Cleaning of plastics and adhesives

We not only have years of experience in handling methylene chloride, but have also developed a new process for cleaning agitator containers in which plastics and adhesives are mixed.

Electrical engineering

Cleaning for electrical engineering

We built a VARIO-L for a company operating throughout Europe in this sector, which degreases up to 864 baskets per day in two working chambers. A very special requirement for this project was the degreasing of the parts in closed shearing boxes. The system is loaded via a three-lane loading device that guides the baskets under a reading bridge with basket detection on their way to the two independently operating working chambers. As the baskets pass, the selected programme is read from a plasticised exchangeable chip and passed on to the control system, which feeds the baskets to the next available working chamber and cleans them accordingly.

The system meets all the customer’s specifications and even exceeds them in terms of throughput per hour: degreasing in closed shearing boxes, basket loading and unloading at the same place, up to two hours of unmanned operation, throughput of 36 baskets per hour.

Medical technology

Cleaning dental and joint implants

The result of the project work and the joint exchange is presented in the form of individual and affordable special systems which, thanks to their needs-based configuration, enable the high standards of the industry to be met in the long term in a process-safe manner.

Surface treatment

Degreasing systems for refined surfaces

Jewellery

Cleaning systems for the jewelry industry

Soon, the VARIO system type had developed a satisfied clientele in many other sectors, such as medical technology, optical industry, etc.

As an insider in the jewellery industry, let us advise you and we will find a customised solution for your company.