Our new VARIO plant series impresses with flexibility in almost every respect.

Find out more in our product overview.

We build cleaning and degreasing plants for industry

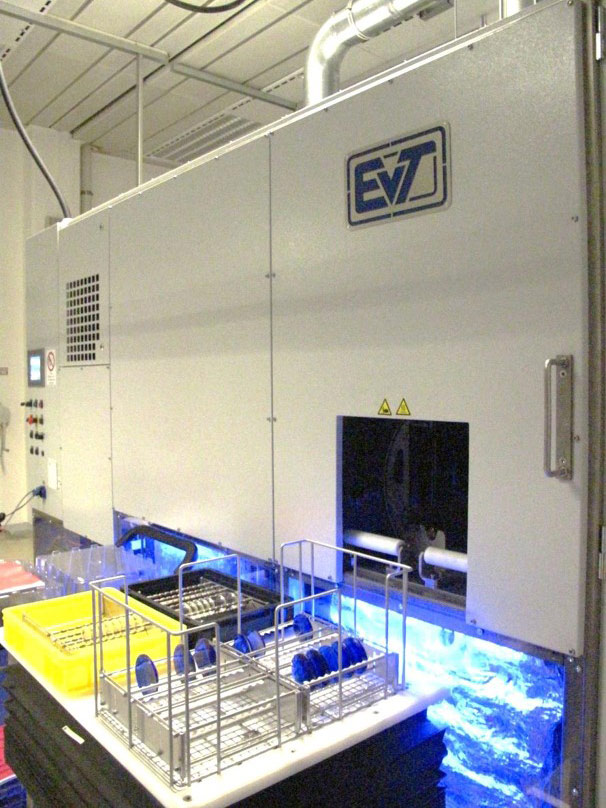

EVT Eiberger Verfahrenstechnik GmbH has been supplying the metalworking industry with parts cleaning systems on an international scale since 1994.

Safe plant technology and highest quality craftsmanship are our top priority.

Our product range includes compact systems for standard baskets as well as special designs that are tailored to your individual requirements.

Solvents of all kinds are used here.

At the same time, water-based cleaning agents are also used.

With our experience of more than 25 years in the field of industrial parts cleaning,

we would be pleased to advise you on the implementation of your cleaning requirements.

This is the basis for your individual cleaning system – get in touch today!

GIGANT – The Extraordinary One

Large parts, high volume/weight throughput, gigantic chamber volumes requiring little space: Our GIGANT performs exceptionally well.

We would be happy to discuss with you in person whether this is the right plant concept for your needs.

VARIO – The Variable One

Components cleaning of all types and materials, in baskets of all dimensions and a variable process design using modern control systems.

Our VARIO is configurable for all common solvents, is highly flexible and customised in every respect.

We would be happy to show you the versatility of this plant system in a personal meeting.

AQUA – The Splashy One

Our AQUA is used where cleaning with solvents is not necessary or not possible, achieving optimum cleaning results with aqueous media.

The compact design and good accessibility allow installing this plant system in any production facility.

We would be delighted to invite you to carry out cleaning tests with your parts in our technology centre.

NANO– The Compact One

The compact, affordable NANO systems are used for cleaning and degreasing small to middle-sized parts and throughputs.

The flexibility of the cleaning process and set-up location allow the NANO to be used in a wide range of industries

EVT Special Solutions

Cleaning of elongated pipes

The cleaning of elongated pipes is not possible with conventional cleaning systems due to pipe lengths of many metres.

Unlike any other company in the cleaning market, we have successfully implemented a great variety of such projects. Pipes of all types and materials are cleaned in these plant systems. The know-how here lies in the details.

For cleaning tests, a test facility is available in our technology centre where we can demonstrate the cleaning of pipe lengths of up to 9 metres.

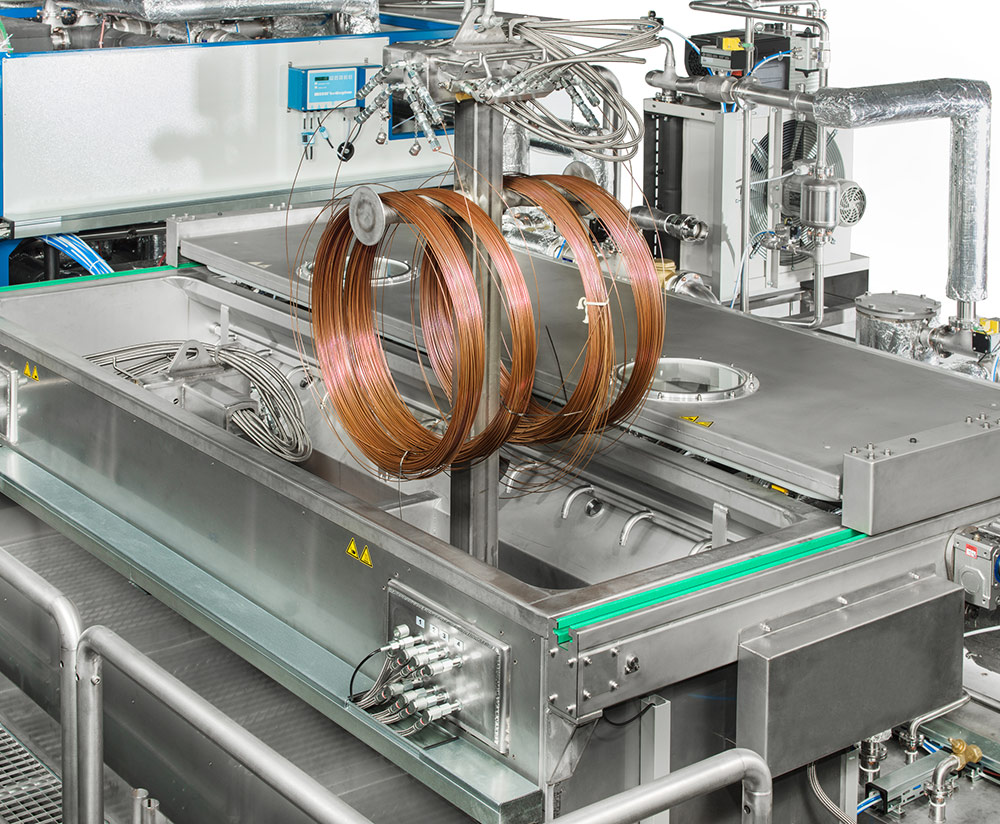

Cleaning tube coils

Cleaning tube coils is a simple matter if you only have to clean the outside. However, cleaning the inside of these tubes is a challenge that can only be mastered by specialists. We have taken on this task, and we have numerous cleaning systems where we can clean tubes with an internal diameter of less than 1 mm and an uncoiled tube length of several kilometres.

You don’t think that’s possible?

We would be delighted to have the opportunity to impress you with the process technology applied in our technology centre for dealing with tube coils.

Cleaning agitator containers

Cleaning the inside of agitator containers in which adhesives, paints or synthetic resin products were previously processed isn’t quite the classic remit in our industry.

We have taken up this challenge and developed a plant system for a well-known manufacturer of washbasins made of artificial marble. They now clean and dry the often heavily soiled agitators without leaving any residues, for example before a colour change.

We would also be happy to address your enquiry and present you our universally applicable plant system.

Our customers are impressed.

Corresponding equipment technology is available for trials in our technology centre.

Challenge us!

Cleaning hardening stock

Whether integrated in the hardening line and automatically fed, or as a stand-alone plant system fed by crane: More than a hundred EVT systems throughout the world ensure a reliable downstream hardening process by reliably degreasing the hardening stock.

We develop and manufacture custom-designed cleaning systems for removing any trace of production substances for hardening shops around the world.

Cleaning optical lenses

We take for granted today, what was unthinkable years ago: The cleaning of protective lacquers, centring oils, light-curing adhesive materials and fillers from optical lenses, without long soaking times, in a closed equipment technology and in an environmentally friendly and process-safe manner. This has been made possible by the development of a process technology specially geared to optics in conjunction with the appropriate cleaning chemicals. Even the most sensitive glasses are cleaned here without damage and without corrosion.

Our numerous customers are impressed.

Corresponding equipment technology is available to you for trials in our technical centre.

Challenge us!

EVT Equipment

DESTOMOBIL

Gentle processing of all common solvents with the aid of state-of-the-art vacuum technology – that is what DESTOMOBIL stands for. You can connect it to any cleaning system. It also works on the barrel-to-barrel principle.

Reduce the solvent content to be disposed of to a minimum! Save disposal costs and protect the environment.

The breakdown of operating costs is also sure to impress you.

DO YOU WANT TO KNOW MORE?

Just give us a call

Phone: +49 (0) 7045 20 38-0

or send us an email.

We are personally at your disposal from

Monday to Friday from 9:00 – 17:00.

CONTACT

EVT Eiberger Verfahrenstechnik GmbH

Ferdinand-von-Steinbeis-Ring 45

75447 Sternenfels

Germany

Tel.:+49 (0) 7045 20 38-0

Fax: +49 (0) 7045 20 38-20

Mail: info(at)evt-gmbh.eu